Best-Selling Diamond Abrasive Pads - 1308 PDC Cutters For Geological Mining With High Wear Resistance – SinoDiam

Best-Selling Diamond Abrasive Pads - 1308 PDC Cutters For Geological Mining With High Wear Resistance – SinoDiam Detail:

1308 PDC Cutters For Geological Mining With High Wear Resistance

1. PDC- Polycrystalline Diamond Compact Introduction

PDC- Polycrystalline diamond compact is composed of polycrystalline diamond layer and tungsten carbide substrate, the polycrystalline diamond layer possesses extremely high hardness and abrasion resistance whereas the tungsten carbide substrate would greatly improve the malleability and weld ability of the whole composite, the polycrystalline diamond compost is used oil well drilling petroleum, geology exploring, coalfield mining and mechanical industry.

PDC cutters for geological mining field drilling bits series are designed for markets in the pursuing of cost. This series PDC are mainly used for producing anchor-shank drill bits, which are equipped with sharp edge, fast footage, high effectiveness, stability, economical and practical advantages.

2. Specification of 1308 Geological Mining PDC Cutter

Diameter: 13.44mm +/- 0.05mm

Height: 8.0mm +/- 0.1mm

Diamond layer thickness: 1.5~2.0mm

Type: Flat face, Convex face, helmet face, ridge face, half cut type.

Application: coal field, mining field etc. geological PDC drill bits.

Wear resistance: about 26000

Impact resistance: 260J

Heat stability: Heat up 750° Celsius and keep warm 10mins.

Destructive test: Use 2kgs heavy hammer free fall one meter height to strike the diamond layer with ten times and no crack,

VTL turning test: VTL testing, the composite sheet from outside to inside – from the inside out turning average of 20 PASSES. Test methods strictly enforce People’s Republic of China Machinery Industry Standard JB / T3235-1999.

3. Other PDC Cutter Shapes

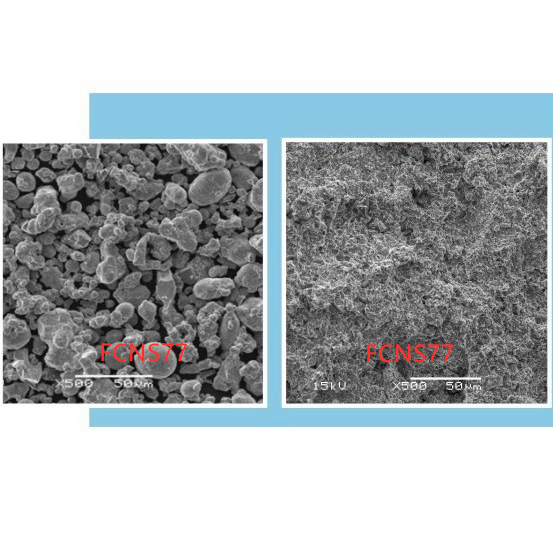

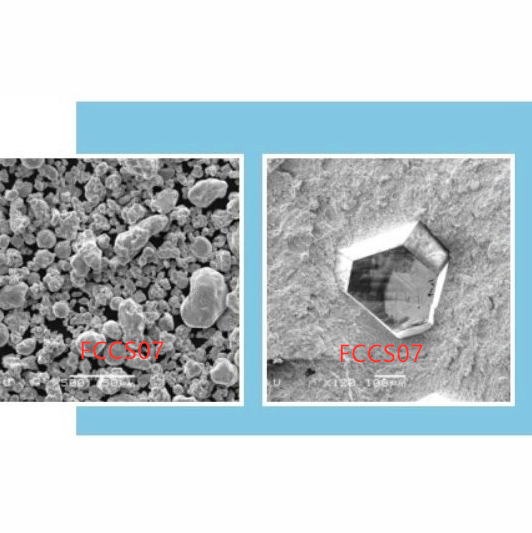

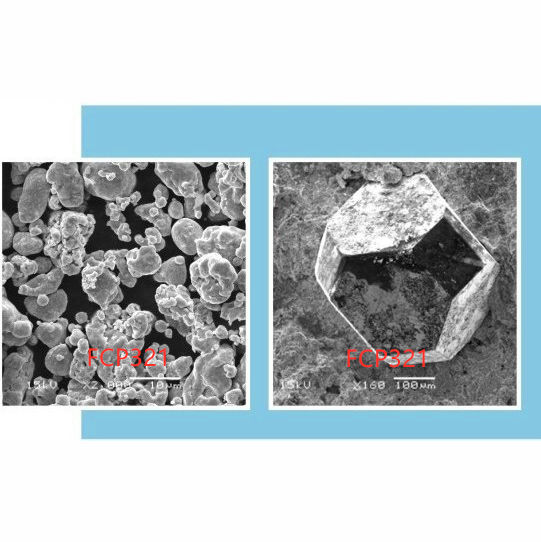

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Best-Selling Diamond Abrasive Pads - 1308 PDC Cutters For Geological Mining With High Wear Resistance – SinoDiam , The product will supply to all over the world, such as: United States, Malaysia, Jersey, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.