SND-M05 Micron Diamond: Budget-Friendly, High-Performance Grinding & Polishing for Stone, Tile, Gem, and Tool Manufacturing

Description

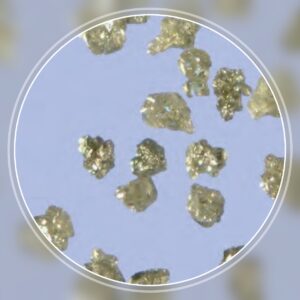

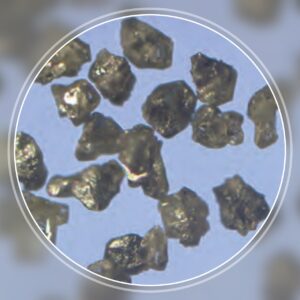

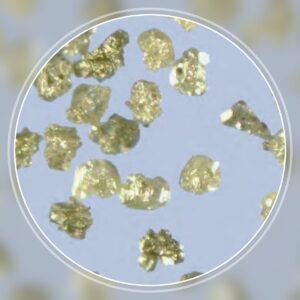

SND-M05 micron diamond boasts an optimized irregular crystal structure with a broad particle size range of 0–0.125~40–60μm, making it the go-to choice for efficient stone, tile, and gem polishing at an affordable price. With impurity levels tightly controlled (total impurities ≤0.5%, nitrogen ≤0.3%, and boron ≤0.1%), this product offers consistency in performance without compromising on durability. Perfect for low-to-medium intensity grinding tasks, it delivers reliable results across multiple industries, providing a cost-effective alternative to higher-end diamond grits.

Technical Edge & Engineering

- Crystal & Impurity Control: Utilizes a precise fracturing process to create irregular, sharp-edged crystals that enhance material removal—perfect for polishing stones, tiles, and gems. The low impurity content prevents discoloration and ensures smooth, clear finishes.

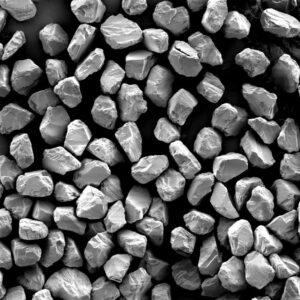

- Particle Size Distribution (PSD): The wide particle size range supports both fine grinding (0–10μm) for smooth finishes and larger particles (30–60μm) for faster material removal. This dual functionality eliminates the need for multiple grades, offering enhanced versatility and performance.

- Thermal Stability & Wear Resistance: Capable of withstanding temperatures up to 650°C, SND-M05 outperforms generic diamonds in wear resistance, with a wear rate of just 1.2–1.5% per hour during marble grinding—extending tool life by 20% compared to standard economy-grade options.

Key Advantages

- Cost-Effective Performance: Offers 15% faster material removal than generic economy diamonds, while being 20% more affordable than mid-tier alternatives. Its affordability and efficiency make it an attractive choice for mid-scale contractors and small workshops.

- Bond Compatibility: Ideal for use with resin and vitrified bonds, ensuring compatibility with DIY and professional-grade tools alike. It provides lasting durability for products like resin-bonded grinding wheels, hobbyist pads, and artisanal polishing products.

- Versatile Applications: Perfect for general-purpose grinding and polishing tasks across stones (marble, limestone), ceramic tiles, and gemstones. Whether for high-speed grinding or precision polishing, SND-M05 excels at delivering consistent and reliable results.

Core Applications Across Industries

- Stone & Tile:

- Residential & Commercial: Used in tile cutting and grinding applications, from small DIY projects to large-scale installations. Provides cost-effective solutions for contractors in tile restoration and surface preparation.

- Historic Restoration: Ideal for gently removing surface weathering from historic stone and tile facades. Offers consistent performance in delicate tasks such as restoring limestone features without damaging the material.

- Gem & Jewelry:

- Gemstone Polishing: Perfect for pre-polishing semi-precious gems like amethyst and garnet, reducing processing time and improving efficiency in jewelry manufacturing.

- Jade Carving: Used in jade carving studios for shaping nephrite and jadeite, helping to reduce micro-cracking and improving yield rates.

- Tool Manufacturing:

- DIY & Consumer-Grade Tools: Integrated into DIY grinding and polishing tools, providing cost-efficient performance that justifies a higher selling price for premium consumer products.

- Custom Tool Production: Enables small batch production of custom polishing pads for tile makers, ensuring consistent performance and reducing tool change frequency.

Technical Specs

- Particle Size Range: 0–0.125~40–60μm

- Crystal Shape: Irregular

- Bond Compatibility: Resin, Vitrified

- Toughness: ★ (Single Yellow Bar)

- Thermal Stability: Up to 650°C

- Impurity Content: ≤0.5% (Nitrogen ≤0.3%, Boron ≤0.1%)

FAQ

Q1: What materials is SND-M05 best for?

A: SND-M05 is best suited for soft-to-medium materials like marble, limestone, ceramic tiles, and jade. For harder materials like granite, consider using SND-M10 or M15.

Q2: Can SND-M05 be used in electroplated tools?

A: SND-M05 is optimized for resin and vitrified bonds. For electroplated tools, we recommend SND-M10 or M15 for better adhesion.

Q3: How does SND-M05 compare to premium micron diamonds?

A: While SND-M05 offers excellent performance for general-purpose tasks, it may not match the precision or toughness of higher-end micron diamonds (M10 or M15). However, it provides great value for users on a budget.

Q4: How does SND-M05’s particle shape improve resin bond retention?

A: The irregular, sharp-edged crystals in SND-M05 lock into resin bonds more effectively than rounded particles, resulting in improved retention and less grit shedding.

Q5: What’s the shelf life of SND-M05, and how should it be stored?

A: SND-M05 has a shelf life of 24 months when stored in moisture-proof packaging. Store in a cool, dry place (15–25°C) with less than 60% humidity to maintain optimal performance.

المراجعات

لا توجد مراجعات بعد.