What Is Cubic Boron Nitride (CBN)?

Cubic Boron Nitride (CBN) is a synthetic superabrasive composed of boron and nitrogen atoms with a diamond-like crystal structure. Produced via High Pressure High Temperature (HPHT) technology, CBN transforms hexagonal boron nitride (h-BN) into a cubic lattice under extreme pressure (5–6 GPa) and temperature (1300–1600°C).

Why CBN Is Ideal for Ferrous Metals

- Exceptional Hardness: Vickers hardness ~45 GPa—far exceeding traditional abrasives like aluminum oxide and silicon carbide.

- High Thermal Stability: Retains structure up to 1400°C, outperforming diamond in machining heat-sensitive ferrous metals.

- Chemical Inertness: Does not react with iron, steel, or ferrous alloys, unlike diamond which forms iron carbide.

- Low Friction: Reduces heat buildup, improves surface finish, and minimizes workpiece deformation.

CBN is widely used in precision grinding, high-speed cutting, and polishing of ferrous metals, including hardened steel, cast iron, titanium, and superalloys.

Core Applications of CBN

1. Metal Machining (CBN Grinding & Cutting)

- Hardened Steel Grinding: Perfect for HRC 50+ steels like automotive gears, bearings, and tool steel components. Enables faster material removal and ultra-tight tolerances (±0.001 mm).

- Cast Iron Processing: Ideal for gray and ductile cast iron parts, including engine blocks and brake discs. Improves tool life and efficiency by 30–50% versus conventional carbide tools.

- Titanium & Superalloys: Critical in aerospace for machining titanium alloys and nickel-based superalloys (e.g., turbine blades), where heat resistance and precision are essential.

2. Precision Polishing

- Mold & Die Polishing: Achieves mirror-like surface finishes (Ra ≤ 0.02 μm) on hard molds, dies, and carbide components.

- Semiconductor & Electronic Components: Polishes stainless steel and other hard parts for high-precision, dust-free operations.

3. Other Industrial Uses

- Stone & Ceramics Polishing: Polishes granite, engineered stone, and advanced ceramics (e.g., alumina valves).

- Tool Coating: Thin CBN coatings enhance wear resistance and extend cutting tool life by 2–3x.

Our CBN Product Line

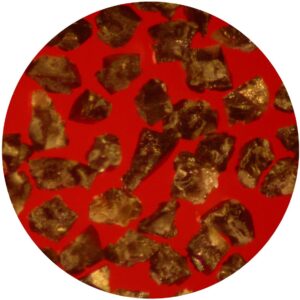

1. CBN-B10: Black Friable CBN – Fine Grinding Specialist

Description: A friable black CBN designed for resin-bonded grinding wheels, delivering ultra-smooth finishes on hardened steel.

- Crystal: Friable (self-sharpening)

- Mesh Size: 50/60 – 325/400

- Recommended Bond: Resin

Key Advantages:

- Continuous self-sharpening prevents glazing and maintains cutting efficiency.

- Achieves ultra-fine surface finish (Ra 0.05 μm) for precision parts.

- Excellent resin bond compatibility for high-speed grinding.

Ideal Applications: Automotive gears, bearing rings, mold inserts, high-speed steel tools.

Learn More

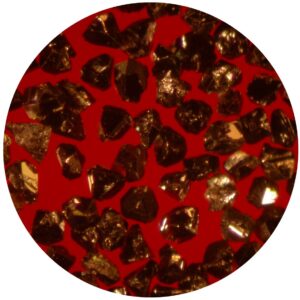

2. CBN-B20: Bright Black Blocky CBN – High-Speed & High-Temp Expert

Description: Blocky black CBN optimized for extreme conditions—heavy-duty grinding, high-speed, and high-temperature applications.

- Crystal: Blocky (impact-resistant)

- Mesh Size: Custom (50/60 – 220/240)

- Recommended Bonds: Resin, Metal

Key Advantages:

- Maintains hardness at 1450°C for demanding steel and cast iron grinding.

- Handles grinding speeds up to 80 m/s, reducing cycle times 20–30%.

- Blocky crystals resist impact, enabling rough-to-finish grinding in one pass.

Ideal Applications: Railway axles, industrial shafts, engine cylinder blocks, brake rotors.

Learn More

3. CBN-A20: Amber Regular CBN – Multi-Bond Versatility

Description: Amber CBN with uniform crystals compatible with vitrified, metal, and electroplated bonds.

- Crystal: Regular (well-formed)

- Mesh Size: 30/40 – 325/400

- Recommended Bonds: Vitrified, Metal, Electroplated

Key Advantages:

- Multi-bond compatibility reduces the need for multiple CBN grades.

- Balanced hardness and toughness for rough grinding and semi-finishing.

- Tight particle size ensures consistent dimensional precision.

Ideal Applications: General steel machining, tungsten carbide-ferrous alloys, intricate mold cavities.

Learn More

4. CBN-A10: Amber Irregular CBN – Cost-Effective Resin Bond Workhorse

Description: Irregular amber CBN designed for resin bond tools, offering reliable performance at competitive prices.

- Crystal: Irregular (jagged edges)

- Mesh Size: 50/60 – 325/400

- Recommended Bond: Resin

Key Advantages:

- Strong bond adhesion prevents crystal detachment.

- Cost-effective for high-volume, non-critical grinding.

- Jagged edges ensure steady material removal without workpiece burn.

Ideal Applications: Carbon steel parts, automotive brackets, fasteners, construction machinery components.

Learn More

Quick Selection Guide: SinoDiam CBN Grades

| Product | Color | Crystal Shape | Mesh Range | Best Bonds | Core Strengths | Target Applications |

|---|---|---|---|---|---|---|

| CBN-B10 | Black | Friable | 50/60–325/400 | Resin | Ultra-fine finish, self-sharpening | Hardened steel precision parts |

| CBN-B20 | Bright Black | Blocky | 50/60–325/400 | Resin, Metal | High-temp, high-speed, impact-resistant | Large components, cast iron |

| CBN-A20 | Amber | Regular | 30/40–325/400 | Vitrified, Metal, Electroplated | Multi-bond, balanced performance | General steel, carbide-ferrous alloys |

| CBN-A10 | Amber | Irregular | 50/60–325/400 | Resin | Cost-effective, strong bond adhesion | Carbon steel, high-volume parts |

Why Choose SinoDiam CBN?

- HPHT-Produced High-Purity Crystals: ≥99.8% purity with precise mesh control.

- Customized Solutions: Mesh sizes and formulations tailored to your materials and machines.

- Expert Consultation: Free technical support for selecting the ideal CBN grade.

- Reliable Quality: Strict testing for hardness, thermal stability, and bond compatibility.

Boost your ferrous metal grinding efficiency, precision, and tool life with SinoDiam CBN.

FAQ: SinoDiam CBN (Cubic Boron Nitride)

1. What is Cubic Boron Nitride (CBN) and why is it used for ferrous metals?

Answer: Cubic Boron Nitride (CBN) is a synthetic superabrasive with a diamond-like crystal structure. Unlike diamond, it does not react with iron or steel at high temperatures, making it ideal for grinding and cutting ferrous metals, including hardened steel and cast iron. CBN delivers superior hardness, thermal stability, and precision.

2. What are the main advantages of CBN over traditional abrasives?

Answer: Compared to aluminum oxide or silicon carbide, CBN offers higher hardness (~45 GPa), extreme thermal stability (up to 1400°C), chemical inertness, and low friction. These properties reduce wear, improve surface finish, and allow high-speed grinding of hardened steels, cast iron, and superalloys.

3. What types of CBN crystals does SinoDiam offer?

Answer: SinoDiam provides four main CBN grades:

- CBN-B10 (Black Friable): Fine finishing, self-sharpening.

- CBN-B20 (Bright Black Blocky): High-speed, high-temperature, heavy-duty grinding.

- CBN-A20 (Amber Regular): Multi-bond versatility (vitrified, metal, electroplated).

- CBN-A10 (Amber Irregular): Cost-effective resin bond grinding.

Each grade is optimized for precision grinding, high-speed cutting, or heavy-duty material removal.

4. Can CBN be used with resin, vitrified, and metal bonds?

Answer: Yes. SinoDiam CBN grades are engineered for resin, vitrified, metal, and electroplated bonds. For example, CBN-B10 and CBN-A10 are ideal for resin-bond tools, while CBN-A20 works with vitrified, metal, and electroplated tools for multi-purpose grinding applications.

5. What materials can be machined with CBN?

Answer: CBN is specifically designed for ferrous metals:

- Hardened steel (HRC 50+)

- Cast iron (gray and ductile)

- Alloy steel, tool steel, and high-speed steel

- Titanium alloys and nickel-based superalloys for aerospace

CBN ensures high precision, fast material removal, and long tool life.

6. How does CBN improve grinding efficiency and surface finish?

Answer: CBN’s self-sharpening crystals, low friction, and thermal stability reduce tool wear and heat generation. This allows consistent cutting, faster material removal, and superior surface finishes, achieving mirror-like precision on hardened steels and complex components.

7. What is the difference between friable and blocky CBN?

Answer:

- Friable CBN (e.g., B10): Breaks into smaller fragments during grinding, exposing fresh sharp edges for fine finishing.

- Blocky CBN (e.g., B20): Thick, impact-resistant crystals designed for high-speed, high-load, and high-temperature grinding.

Choosing the right type depends on grinding speed, load, and surface finish requirements.

8. Can CBN be used for precision polishing of molds and dies?

Answer: Yes. CBN is widely used in mold and die polishing, semiconductor component finishing, and carbide surface refinement. Its hardness and low friction allow mirror-like finishes (Ra ≤ 0.02 μm) without damaging the workpiece.

9. How do I choose the right CBN grade for my application?

Answer: Consider:

- Material type (hardened steel, cast iron, superalloy)

- Bond type (resin, vitrified, metal, electroplated)

- Grinding type (rough, semi-finishing, fine finishing)

- Speed and temperature conditions

Use SinoDiam’s CBN Quick Selection Guide or contact our technical team for custom recommendations.

10. Why choose SinoDiam CBN for industrial grinding?

Answer: SinoDiam CBN is HPHT-produced with ≥99.8% purity, precise mesh control, and consistent crystal quality. We offer custom formulations, free application consulting, and strict quality testing, ensuring maximum efficiency, precision, and cost-effectiveness in ferrous metal grinding and high-speed applications.

المراجعات

لا توجد مراجعات بعد.