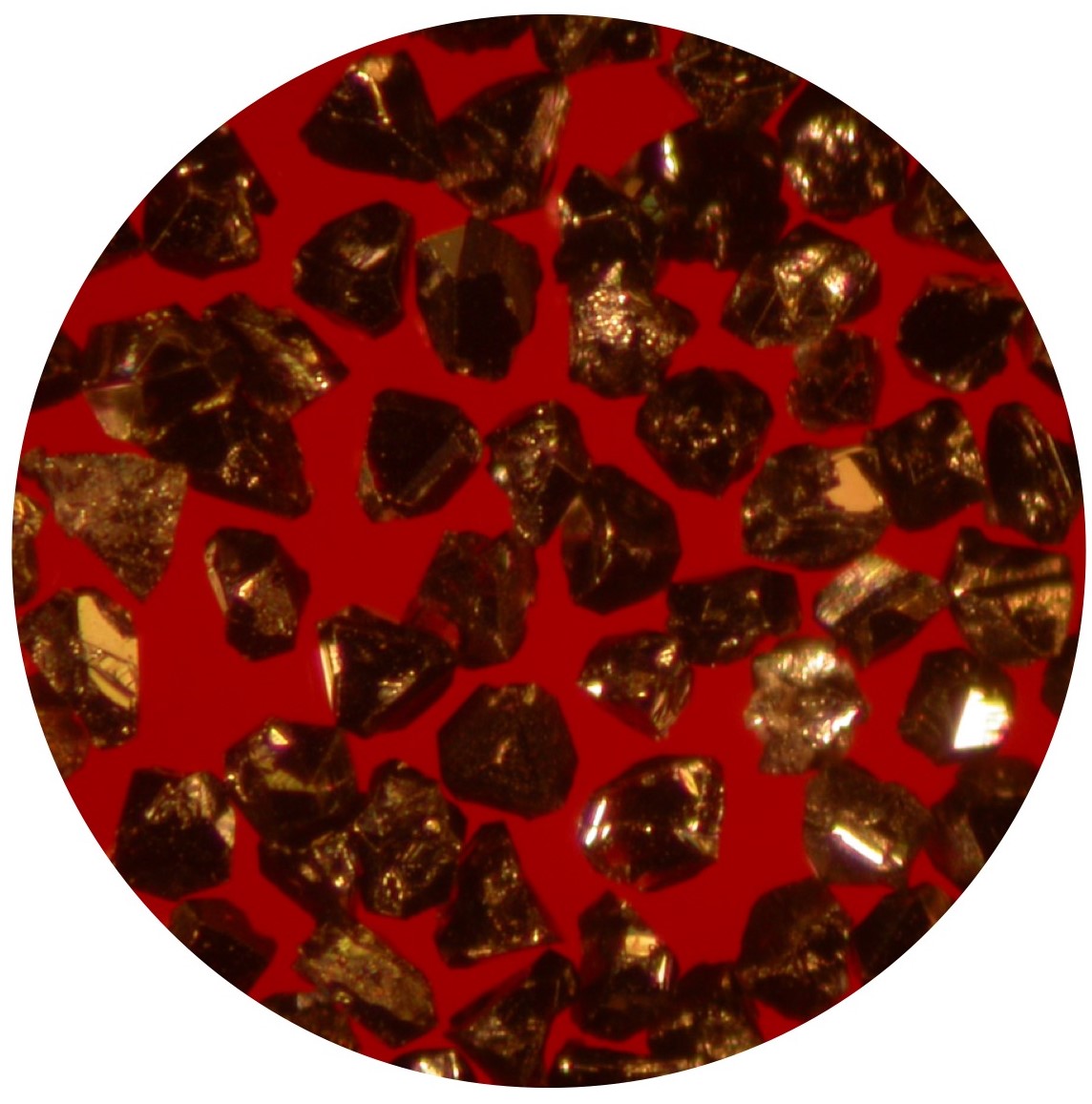

🧩 CBN-B20 Bright Black Blocky CBN – High-Temp / High-Speed Grinding Expert

Product Code: CBN-B20

Mesh Size Range: 50/60–325/400

Color: Bright Black

Manufacturer: SinoDiam

CBN-B20 is a premium bright black cubic boron nitride (CBN) abrasive designed for high-temperature and high-speed grinding applications. Featuring a blocky mono-crystalline structure and exceptional toughness, it performs under extreme thermal and mechanical stress—ideal for vitrified, metal, and electroplated bond systems.

Developed for industrial machining of hardened steel, high-alloy steel, and cast iron, CBN-B20 maintains crystal integrity at temperatures up to 1,300°C, delivering 40% longer tool life and achieving a mirror finish (Ra ≤1.0μm) even at speeds exceeding 8,000 RPM.

Product Highlights & Advantages

✅ Extreme Temperature Endurance (≤1,300°C)

Engineered for high-speed, high-load grinding of ferrous metals where heat stability is critical. CBN-B20’s structure resists thermal degradation, ensuring consistent cutting force and minimal workpiece burn.

✅ Blocky Mono-Crystalline Strength

Uniform cubo-octahedral morphology provides superior impact resistance and edge retention, allowing excellent bond retention in metal and vitrified tools for continuous industrial operation.

✅ Optimized for Hard Ferrous Materials

Specifically tuned for hardened steels (HRC 50+), tool steels, high-speed steels (HSS), and cast iron, outperforming conventional black CBN and CBN-A20 by 30–40% in lifespan and stability.

✅ Superior Surface Finish & Tool Life

Produces mirror-grade finishes (Ra ≤1.0μm) in precision grinding. Ensures consistent wear ratio and reduced wheel dressing frequency—ideal for production lines requiring repeatable accuracy.

✅ Bond System Versatility

Compatible with vitrified bond, metal bond, and electroplated bond formulations. Whether used in CBN grinding wheels, honing stones, or plated rotary tools, B20 ensures strong adhesion and uniform wear.

Technical Specifications

| Item | Details |

|---|---|

| Product Code | CBN-B20 |

| Color | Bright Black |

| Crystal Shape | Blocky Mono-Crystalline |

| Toughness | High |

| Thermal Stability | Up to 1,300°C |

| Available Mesh Sizes | 50/60–325/400 |

| Bond Compatibility | Vitrified, Metal, Electroplated |

| Recommended Materials | Hardened Steel (HRC 50+), Cast Iron, High-Speed Steel, Alloy Steel |

| Typical Grinding Speed | 8,000+ RPM |

| Surface Finish | ≤ Ra 1.0μm |

Applications

- High-speed grinding of hardened tool steels

- Precision finishing of cast iron and alloy steels

- Manufacture of CBN grinding wheels and honing tools

- Use in electroplated rotary tools for ferrous alloys

- Continuous industrial machining environments with elevated thermal loads

FAQ

Q1: What makes CBN-B20 suitable for high-temperature grinding?

A: CBN-B20 withstands up to 1,300°C due to its dense mono-crystalline structure, preventing oxidation and breakdown during high-friction, high-speed grinding of hardened steels.

Q2: How does CBN-B20 compare to standard black CBN?

A: Compared to CBN-A20, CBN-B20 offers 40% longer lifespan, higher fracture resistance, and improved surface uniformity when grinding cast iron or alloy steels.

Q3: What mesh size should I select for precision vs. rough grinding?

A:

- 80/100–140/170 mesh: Optimal for high-speed, heavy-load grinding.

- 200/230–325/400 mesh: Ideal for precision finishing or fine surface polishing.

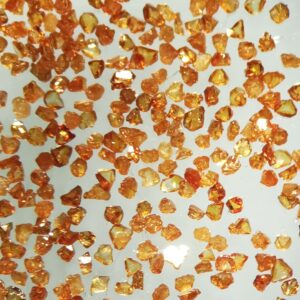

CBN-A20 Amber Regular CBN for Vitrified, Metal, and Electroplated Multi-Bond Tool Applications

المراجعات

لا توجد مراجعات بعد.