A10 Amber Color Cubic Boron Nitride Abrasive Powder For Resin Bond Application

A10 Amber Color Cubic Boron Nitride Abrasive Powder For Resin Bond Application

1. Cubic Boron Nitride Introduction

CBN (cubic boron nitride) superabrasive is with high hardness and high temperature resistance, four times that of traditional abrasive in wear resistance, and have extraordinary thermal conductivity. CBN is widely used in grinding manufacturing market, from aerospace superalloys and thermal spraying to the hardened steel in automotive bearing and gear industry to improve efficiency and get the shortest processing time.

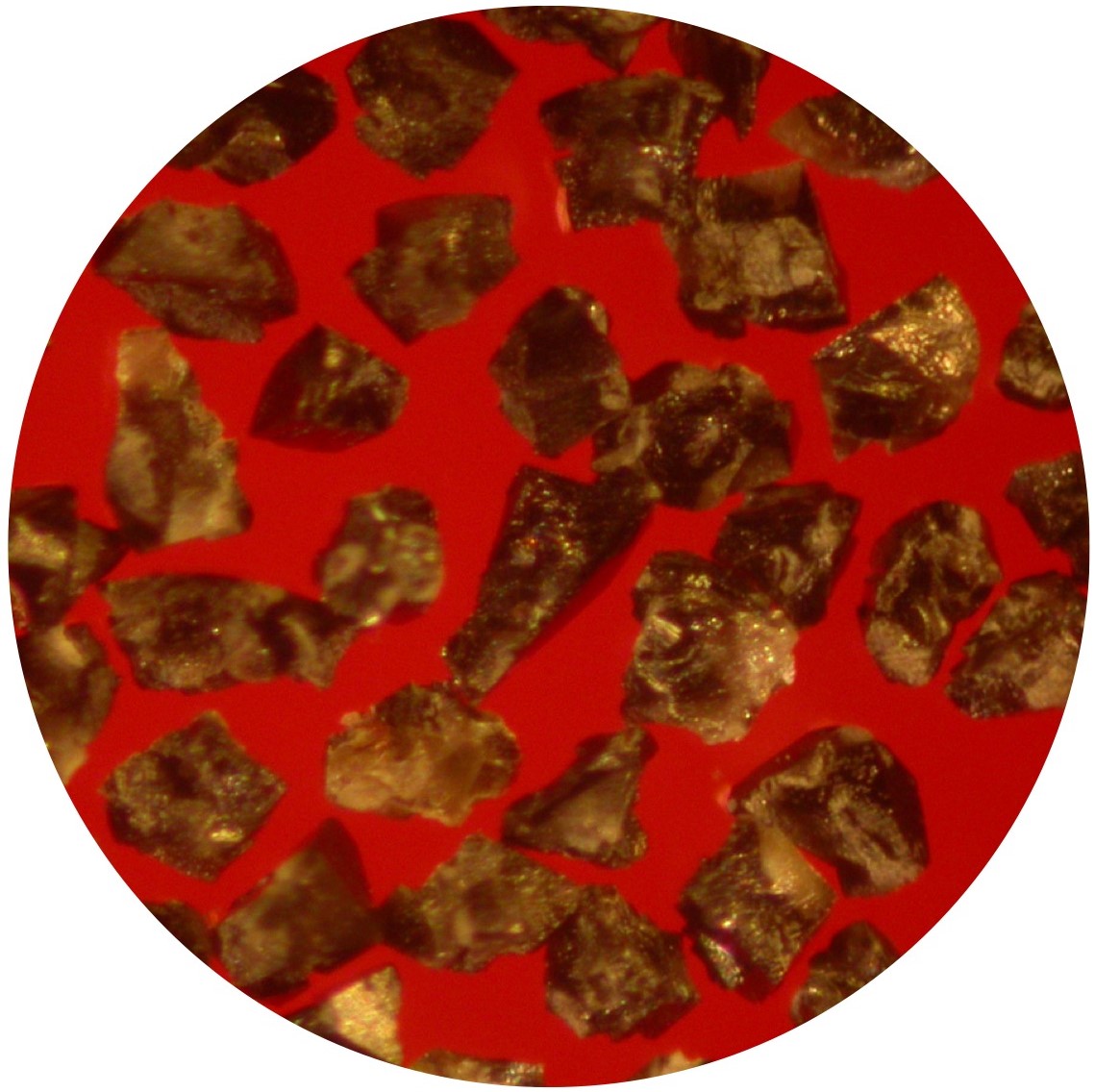

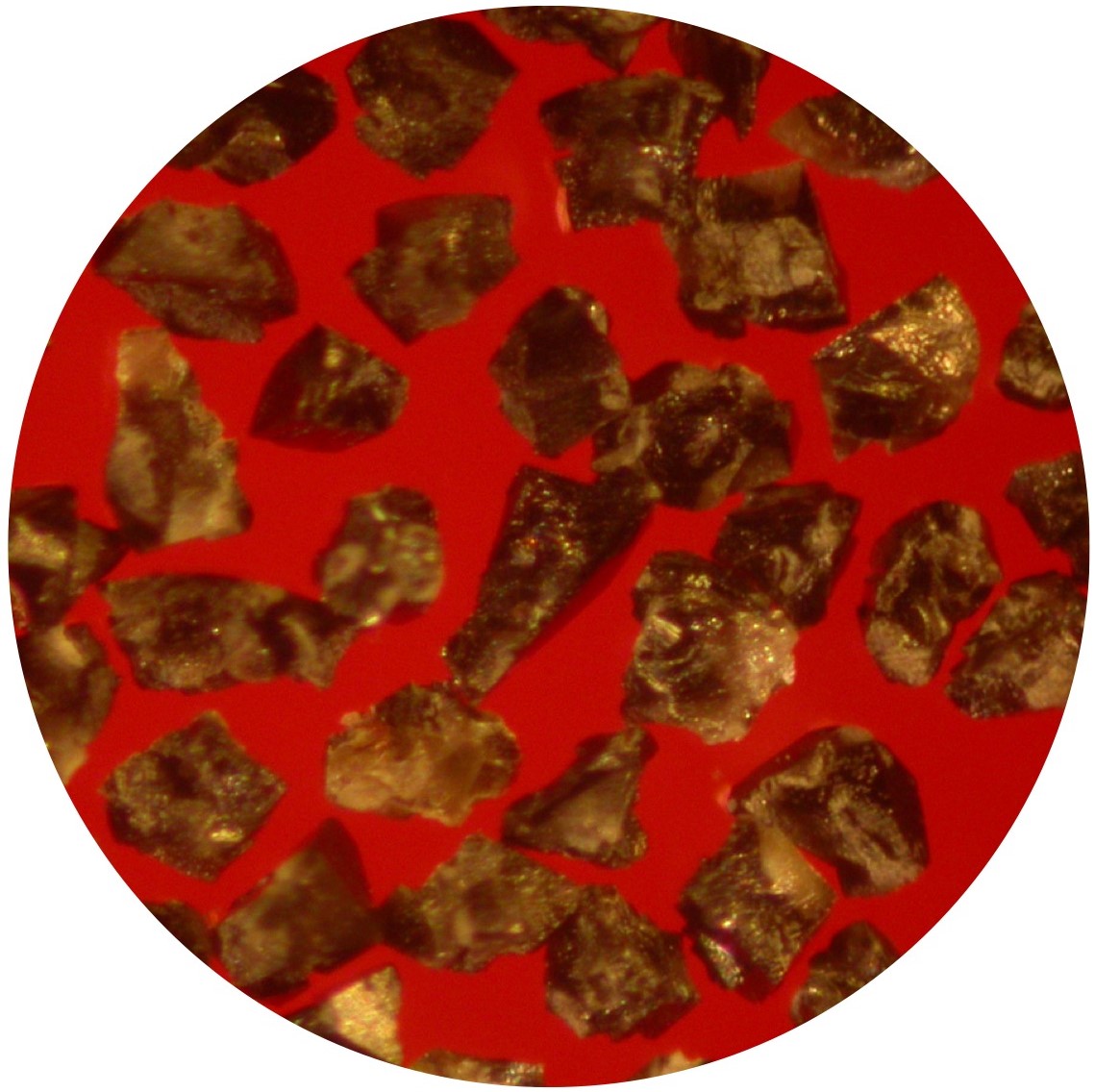

CBN-A10, Amber color, medium strength, irregular shape, good self-sharpness, mainly use in resin bond system.

2. Character of CBN powder

|

|

|

|

|

|

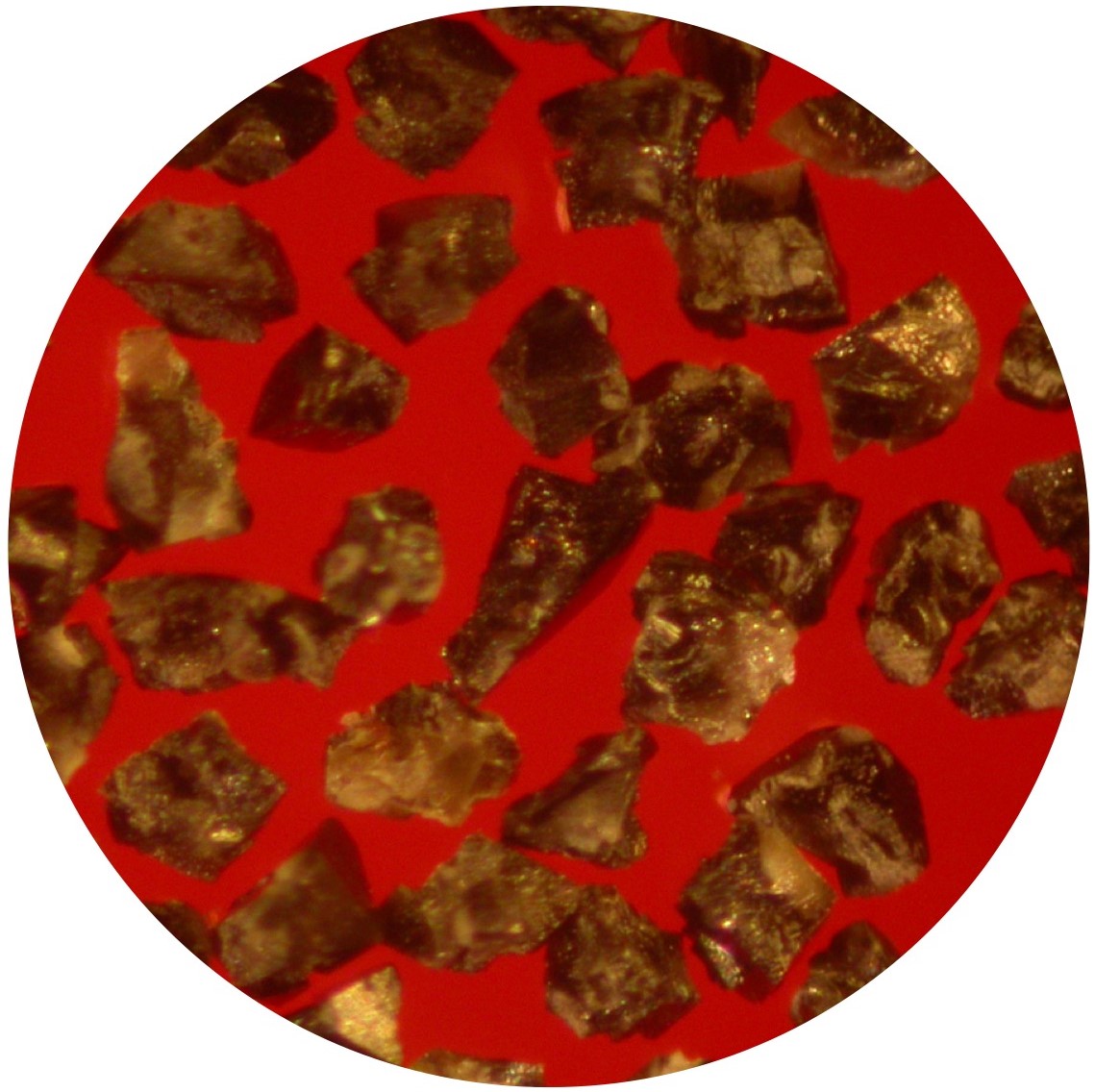

CBN-B10 |

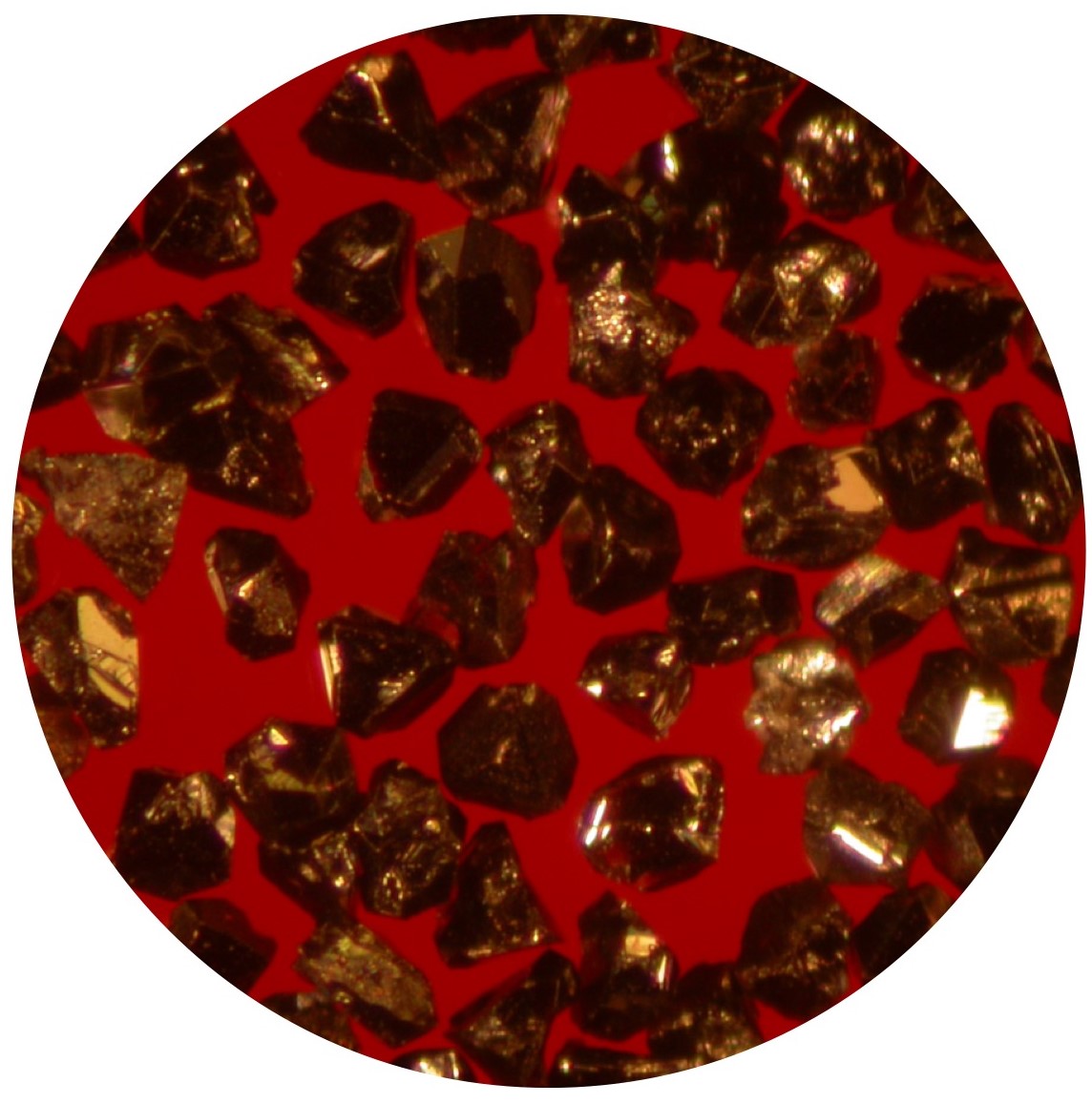

CBN-B20 |

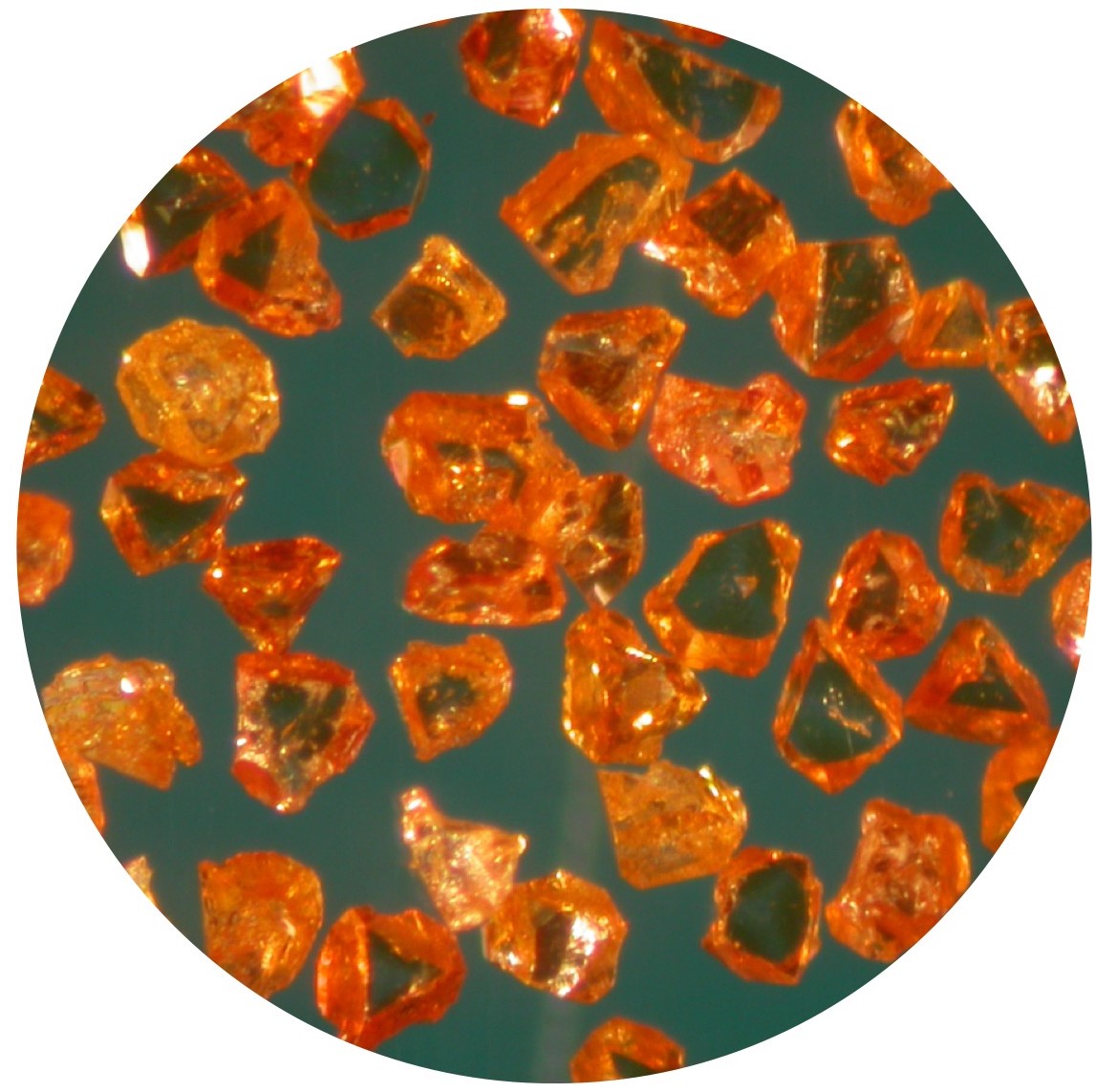

CBN-A10 |

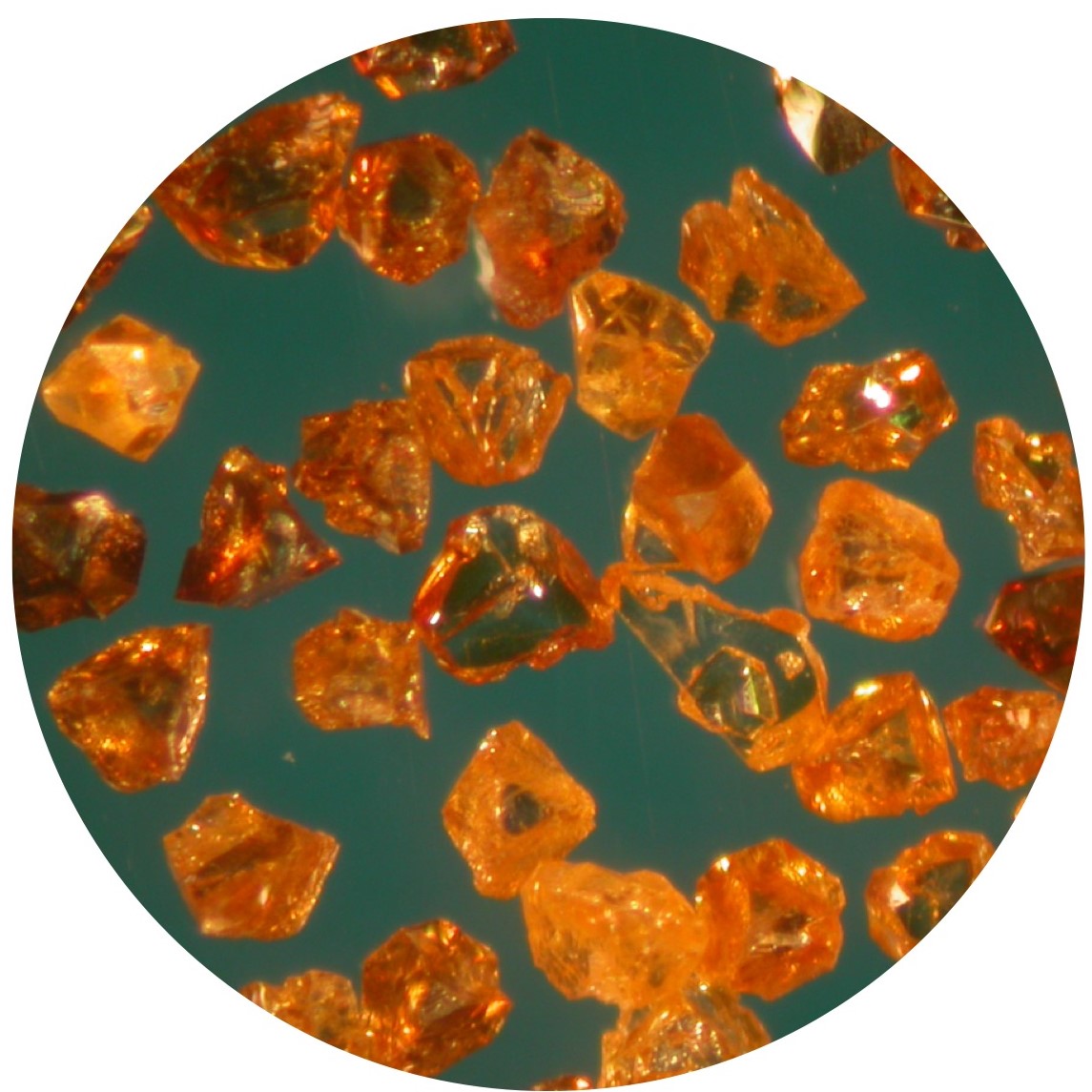

CBN-A20 |

|

CBN-B10, with black color, irregular shape, medium toughness, high thermal stability, protruding acute angle, used in resin and vitrified bond system, providing high performance and efficiency. |

CBN-B20, Bright black, opaque, blocky crystal, with complete and regular crystal, high toughness, higher impact resistance and thermal stability, and thermal stability. Used in vitrifiedl bond system and electroplated grinding tools to process ferrous metals and alloys |

CBN-A10, Amber color, medium strength, irregular shape, good self-sharpness, mainly use in resin bond system |

Golden color, blocky crystal shape, high strength, high thermal stability, widly used in electroplating tools, metal bond, vitrified bond system. |

4. Available Mesh Size

|

60/70 |

70/80 |

80/100 |

100/120 |

120/140 |

140/170 |

170/200 |

200/230 |

230/270 |

270/325 |

325/400 |

|

|

CBN-B10 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

CBN-B20 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

CBN-A10 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

CBN-A20 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

5. CBN Micron Size

| International Standard | China Standard | Mesh Size | Application |

| 0-0.1 | W0.1 | 100000 | Super Mirror Polishing |

| 0.0.25 | W0.25 | 60000 | Super Mirror Polishing |

| 0-0.5 | W0.5 | 30000 | Mirror Polishing |

| 0-1 | W1 | 15000 | Mirror Polishing |

| 0-2 | W1.5- | 13000 | Fine Polishing |

| 1-2 | W1.5 | 12000 | Fine Polishing |

| 1-3 | W2.5 | 10000 | Fine Polishing |

| 2-4 | W3.5 | 6500 | Fine Polishing |

| 2-5 | W4 | 5000 | Fine Polishing |

| 3-6 | W5 | 4000 | Fine Polishing |

| 4-6 | W6 | 3500 | Fine Polishing |

| 4-8 | W7 | 3000 | Normal Polishing |

| 4-9 | W10 | 2500 | Normal Polishing |

| 5-10 | W10 | 2000 | Normal Polishing |

| 6-12 | W10 | 1800 | Normal Polishing |

| 8-12 | W12 | 1600 | Normal Polishing |

| 7-14 | W14 | 1500 | Normal Polishing |

| 8-16 | W14 | 1300 | Normal Polishing |

| 10-20 | W20- | 1200 | Normal Polishing |

| 12-22 | W20 | 1000 | Normal Polishing |

| 15-25 | W20+ | 800 | Normal Polishing |

| 20-30 | W28 | 700 | Normal Polishing |

| 22-36 | W28+ | 600 | Rough Grinding |

| 20-40 | W40- | 500 | Rough Grinding |

| 30-40 | W40 | 450 | Rough Grinding |

| 35-45 | W40+ | 400 | Rough Grinding |

| 36-54 | W50 | 350 | Rough Grinding |

| D46 | 325/400 | 320 | Rough Grinding |

| D54 | 270/325 | 270 | Rough Grinding |

| D64 | 230/270 | 230 | Rough Grinding |

| D76 | 200/230 | 200 | Rough Grinding |