2021 High quality Industrial Diamond Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam

2021 High quality Industrial Diamond Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam Detail:

FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCZ925

|

Main Element | Fe, Cu, Zn |

| Theoretical Density | 8.01g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1200Mpa | |

| Hardness | 98-102HRB |

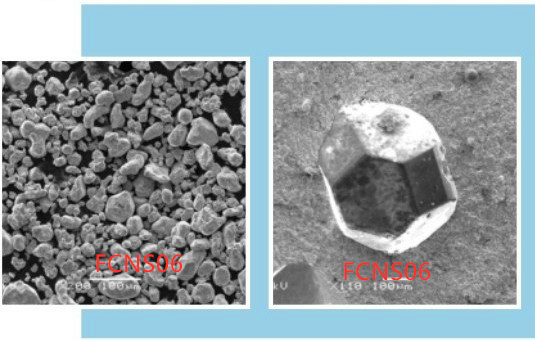

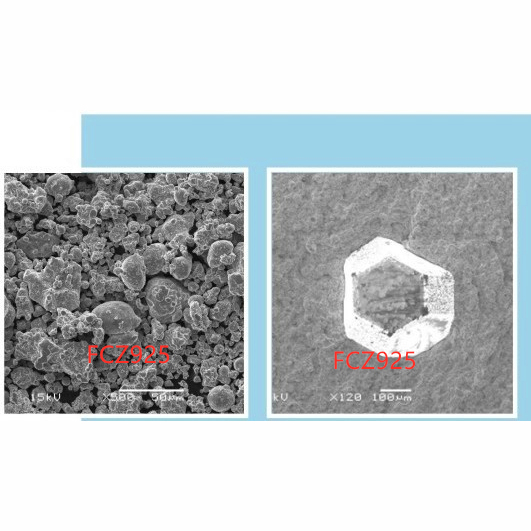

3. FCZ925 Pre-alloyed Powder Character

- This FCZ925 pre alloyed powder has a good wetting and holding ability to the diamond, low bulk density, easy cold forming and great sharpness.

- Applied to medium diameter granite saw blade, granite muti cutting blades, segments for graite blade.

4. Usage Instruction for Granite Muti Cutting Blade

- Metal Powder

- 50-70% FCZ925

- + 10-20% Cu

- + 1-3% Sn

- +5-10% Zn

- + Fe for balance

B. Diamond

- 35/40 @ 30%

- 40/45 @ 50%

- 45/50 @20%

- Diamond Concentration @ 30-35%

C. Sintering Temperature 790-810℃

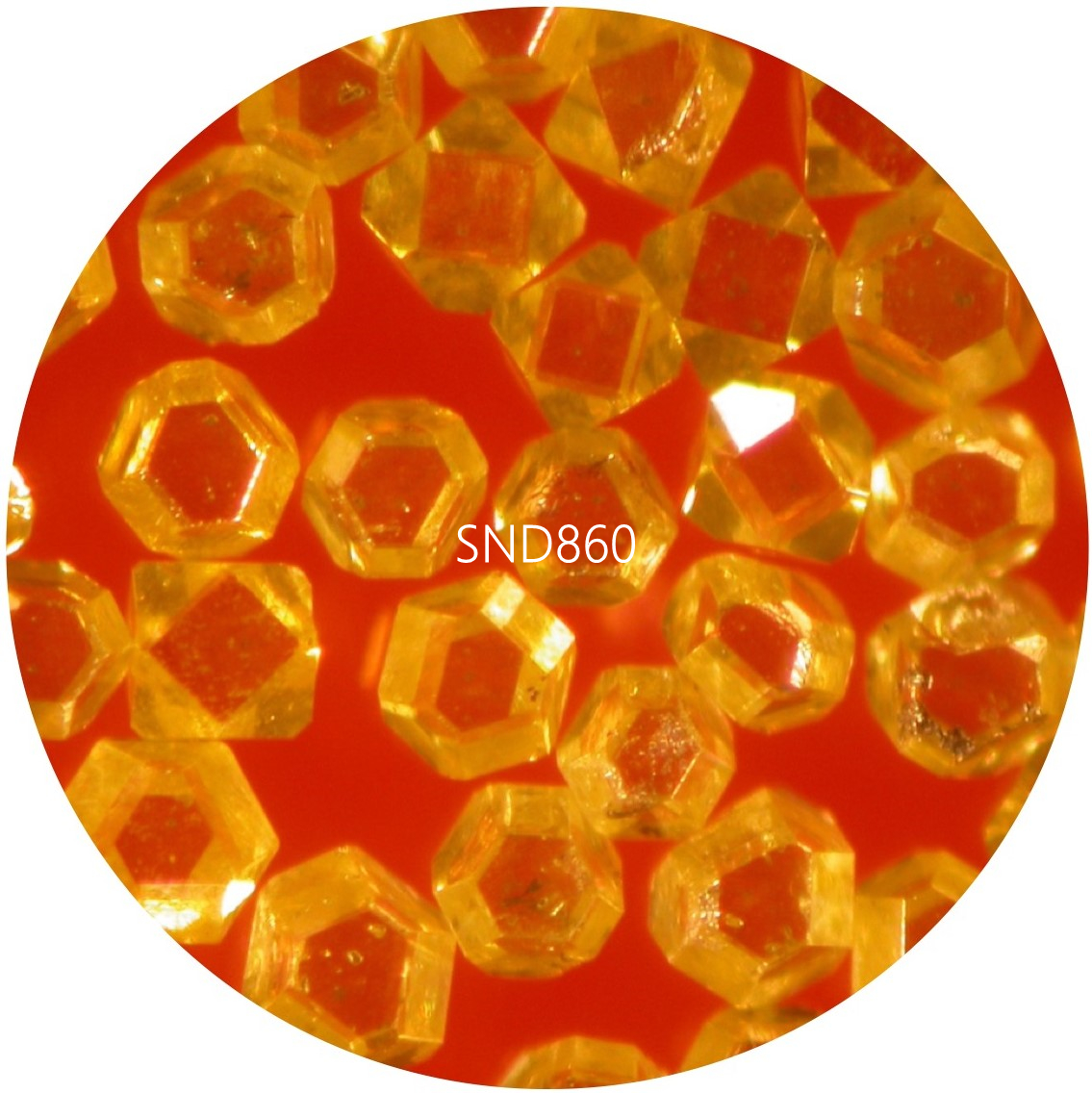

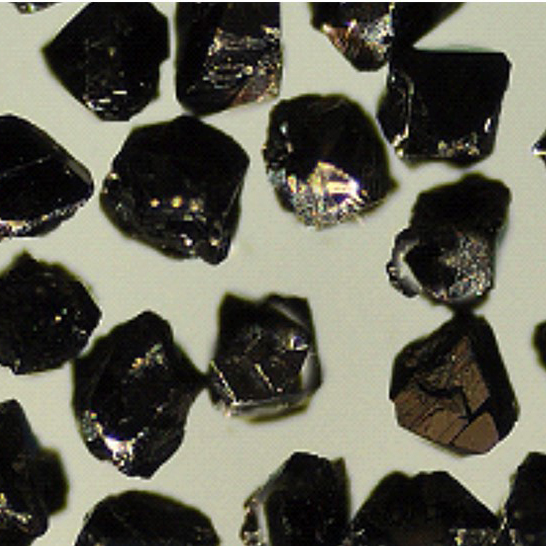

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is "You come here with difficulty and we supply you with a smile to take away" for 2021 High quality Industrial Diamond Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam , The product will supply to all over the world, such as: Benin, London, Honduras, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.