100% Original Factory Fine Polish Paste - Polycrystalline Cubic Boron Nitride (PCBN) for Machining Applications – SinoDiam

100% Original Factory Fine Polish Paste - Polycrystalline Cubic Boron Nitride (PCBN) for Machining Applications – SinoDiam Detail:

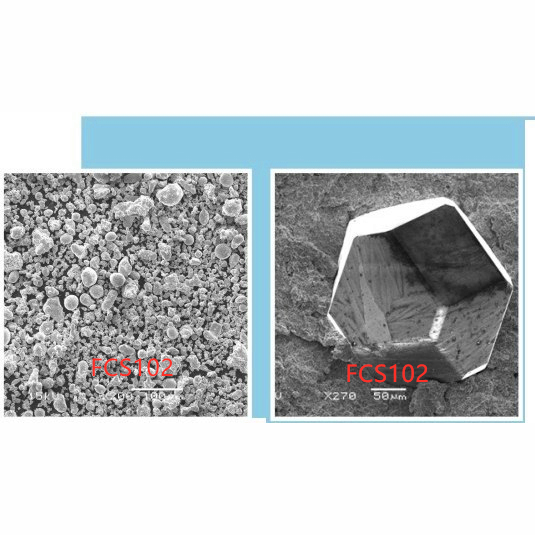

PCBN composites are produced by sintering micron CBN powder with various ceramic, so as to produce extremely hard and thermally stable tooling materials Most PCBN material are integrally bonded to a cemented carbide substrate. CBN is the second hardest material known after synthetic diamond, but has high thermal and chemical resistance properties. It is mainly used in cutting and processing of high hardness or difficult to process materials including hardened steel, grey and high strength cast iron, high speed steel, cast iron quench alloy, sintering metal materials, etc.

|

Code # |

Diameter (mm) |

Diamond layer (mm) |

Height(mm) |

Abrasive ratio |

Feature |

Application |

|

HC1303 |

13.5 |

0.8-1.0 |

3.2 |

> 10000 |

CBN layer and Wc-co substrate High CBN content 2. High wear resistance 3. Good rupture strength 4.Good chemical stability |

1. Precise dimension2. Grey cast Iron3. Powered Metal4. Heat resisting

5. Quench alloy 6. Tools steel & die steel |

|

HCF1304 |

13.5 |

0.8-1.0 |

4.5 |

|||

|

HC3201 |

32.0 |

0.8-1.0 |

1.6 |

|||

|

HC3202 |

32.0 |

0.8-1.0 |

2.4 |

|||

|

HC3203 |

32.0 |

0.8-1.0 |

3.2 |

|||

|

LC1303 |

13.5 |

0.8-1.0 |

3.2 |

>3000-4000 |

CBN layer and Wc-co substrate 2. Relatively low CBN content 3. High wear ratio 4. Good anti-rupture strength |

metallurgy parts |

|

LC1304 |

13.5 |

0.8-1.0 |

4.0 |

|||

|

LC3201 |

32.0 |

0.8-1.0 |

1.6 |

|||

|

LC3202 |

32.0 |

0.8-1.0 |

2.4 |

|||

|

LC3203 |

32.0 |

0.6-0.8 |

3.2 |

|||

|

HB0903 |

9.55 |

3.18 |

3.18 |

> 5000 |

|

|

|

HB1204 |

12.7 |

4.76 |

4.76 |

|||

|

HB1608 |

15.85 |

8.0 |

8.0 |

|||

|

HB2008 |

20.0 |

8.0 |

8.0 |

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for 100% Original Factory Fine Polish Paste - Polycrystalline Cubic Boron Nitride (PCBN) for Machining Applications – SinoDiam , The product will supply to all over the world, such as: Auckland, Cape Town, Mexico, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.